Ceruna

CERUNA is an interactive socket system designed to create a green environment for the Pulse Building. Engaging light patterns and moving sockets capture the users’ attention and show them whether there is solar energy available. The playful interactions keep users interested and open to CERUNA’s messages, motivating them to charge their devices at the right time.

Charging devices when solar power is available maximizes the use of green energy which in turn prevents the need for grey energy at a later stage. In this way CERUNA enables the Pulse building to use individuals’ device batteries as cells in its power storage.

With a multidisciplinary team of six we have spent the past two and a half months designing an interactive socket system that raises awareness about energy consumption and maximizes the use of solar energy.

Students: Judith Cohen, Bart van Dijk, Marleen Dohmen, Sarah de Herde, Daniël Hesselman, Kati de Jong.

Coaches: Martin Havranek, Aadjan van der Helm, Wouter van der Hoog, Tomasz Jaskiewicz.

User research

We were briefed to design an interactive socket system focused on raising awareness about energy consumption. To find out how we could shape this in a way that it also fulfils user needs, we started our design process by doing user research. From this, we learned that most people don’t want to be distracted or bothered with an extra effort when working. This led us to the conclusion that for our socket system to work, we should design it in such a way that people actually enjoy using it. It should be fun!

We also conducted user research in a later stage to test CERUNA’s light patterns on comprehensibility. CERUNA’s light patterns show users whether there is solar energy available and either motivate or demotivate them to charge their devices. In order for this to work, they should be easy to understand. We made several animations to represent the light patterns and used the findings to further develop them.

Production process

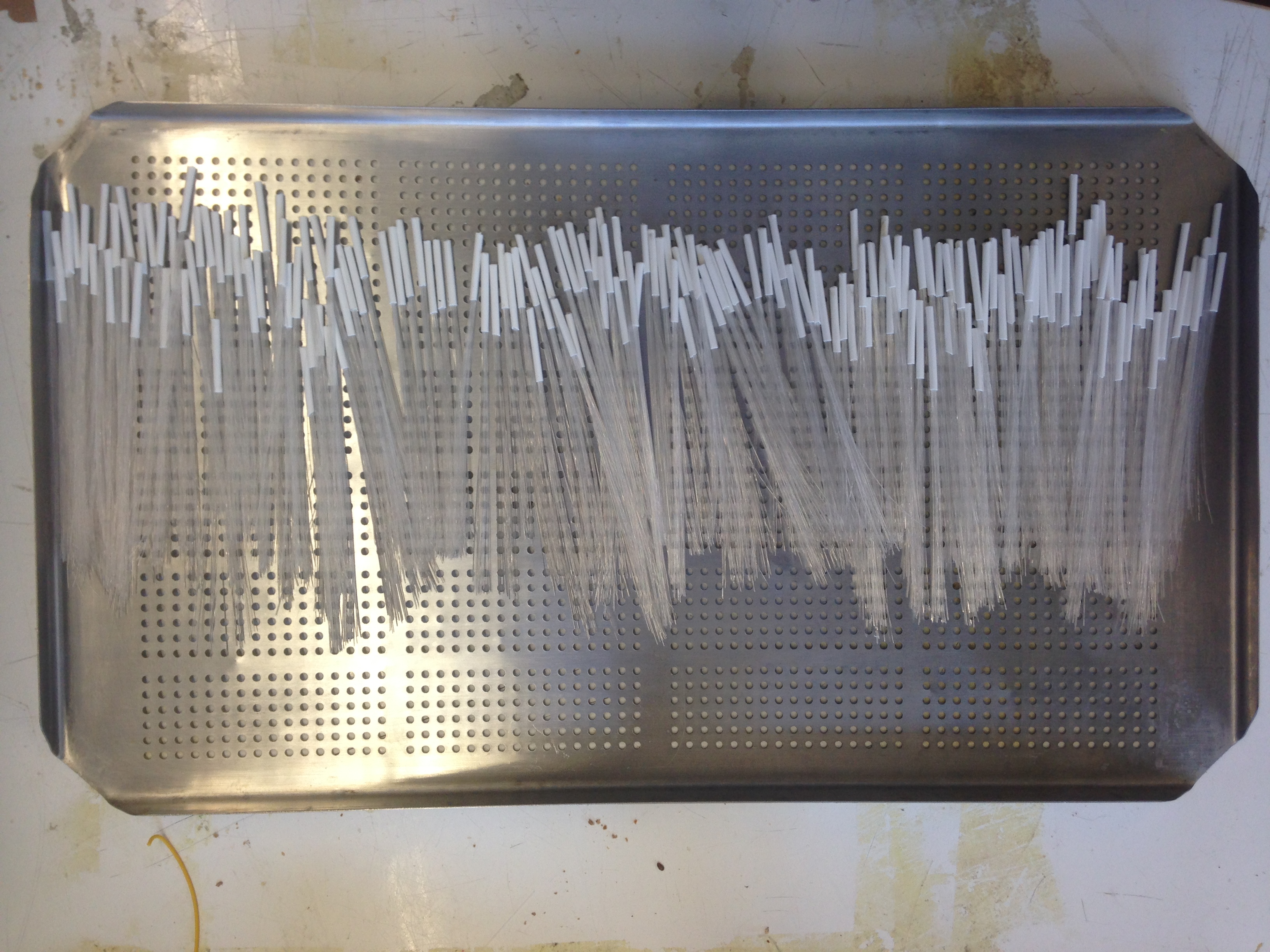

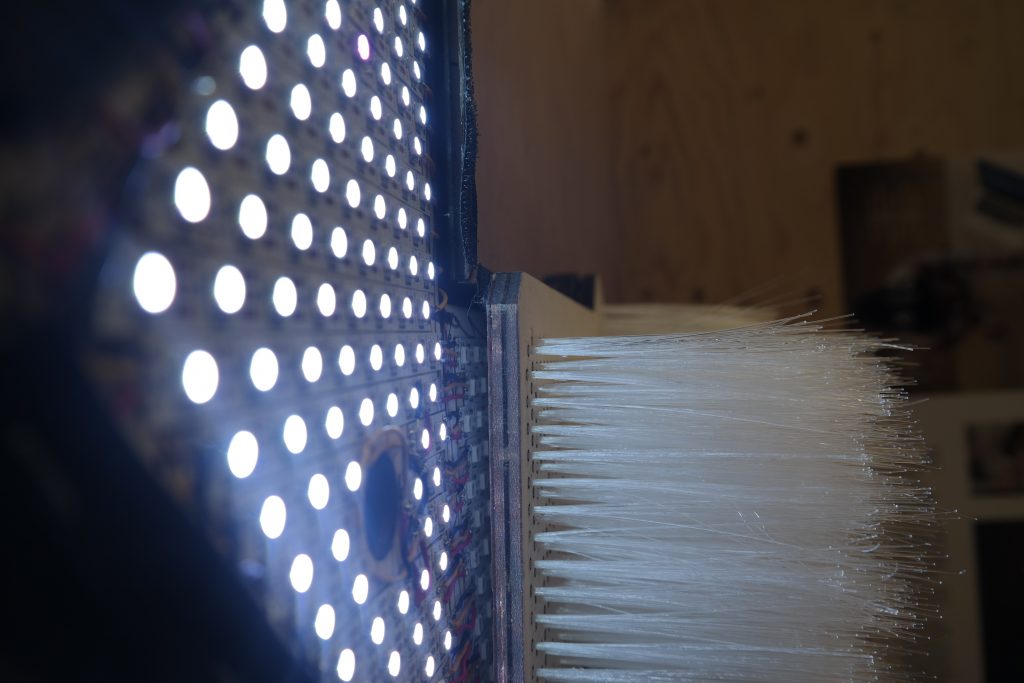

CERUNA is made up out of thousands of little pieces of fiber optic. These fiber bundles are then placed in small holes in the wall and table prototype. The biggest challenge in producing these fiber bundles was finding a way to ensure that they all had the same diameter, making it easier to place them in the holes.

After trying out various ways to produce the fiber bundles we found that the quickest and most successful way was to count 20 fibers, put them in a shrinking sleeve and put theise bundles in the oven for 30-60 minutes.

We used CNC milling and laser cutting to fabricate 3mm width holes for the fibre bundles. After coming out of the oven the bundles were placed in the holes of the prototype, where they were secured with glue. They were cut at the same length at the back of the prototype.

70 % of all the produced bundles were able to fit into the holes in the prototypes. The wall and table combined are built out of approximately 4400 fibre bundles, all handmade!

Electronics

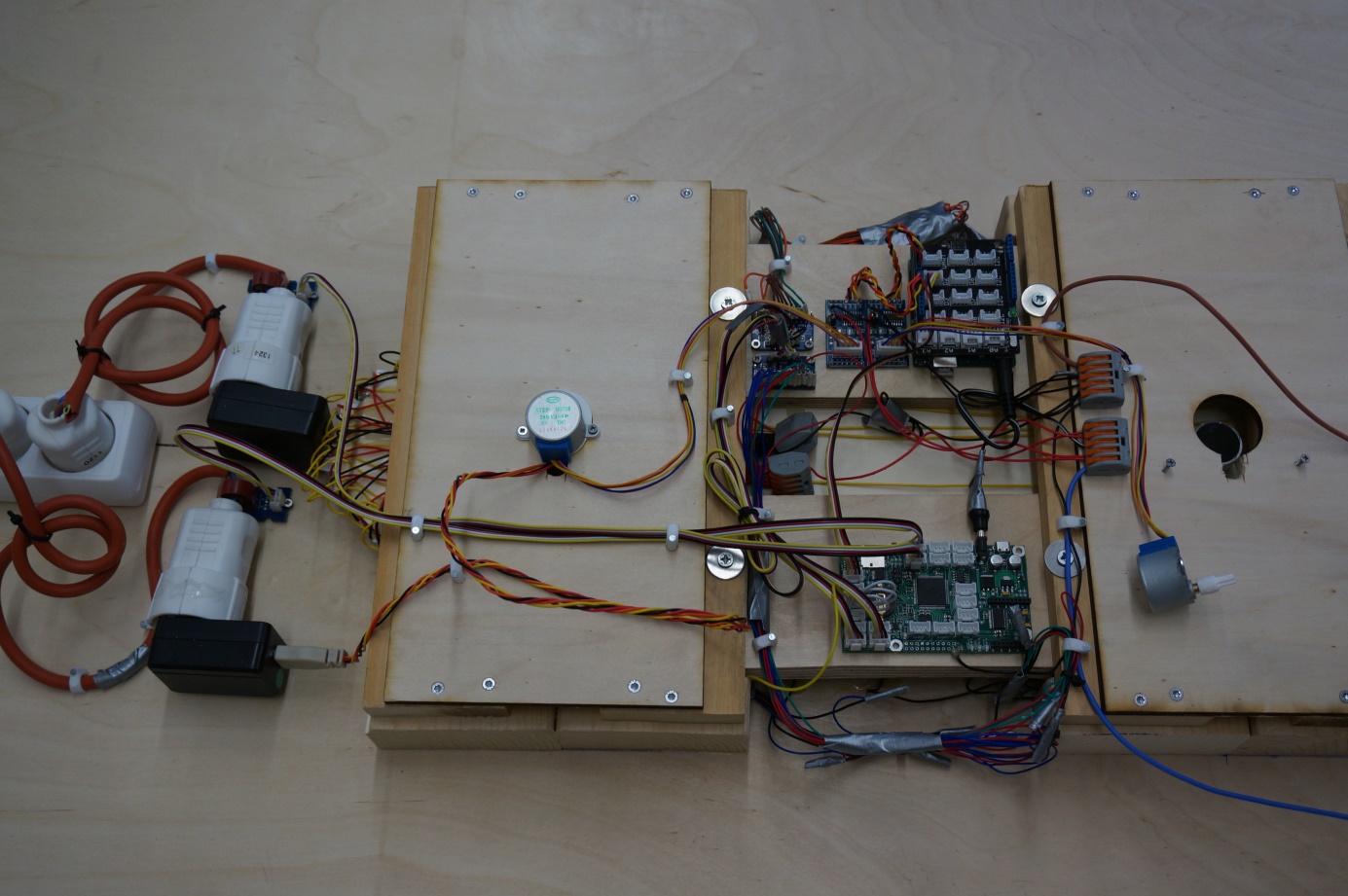

In order to illuminate the tens of thousands of little optical fibres, LED lights are needed. The LED lights are able to emit every colour into the bottoms of the optical fibres. A lot of LEDs are needed because the fibres need to be illuminated exactly from beneath. If all the LED’s would be illuminated, they would need a lot of power. And in order to be able to communicate properly to the LED’s, they need to be able to access this power. Which is why a special external power supply was needed to power the LED’s. In practice, not every LED is being turned on at the same time, so extreme power usage never occurs.

In order to communicate to all the LED’s, we needed a microcontroller that was able to tell every LED when to turn on, when to turn off, and what colour they should be. There were multiple micro-controllers needed in order to communicate properly to the extreme amount of LED’s and stepper motors of which CERUNA consists. Also, a separate micro-controller was needed in order to communicate to the remote control properly. The power supply needed for the LED’s, USB-sockets, steppers and micro-controllers are all fit in one package, which is completely concealed in the table and wall.

A separate small device acts as a remote, so we were able to cycle through all the modes CERUNA offers during the presentation.

Socket movement

To achieve the moving mechanism for the sockets we used a linear actuator in combination with a stepper motor. The linear actuator can be pushed on without putting stress on the stepper. Which is necessary because people will push on the socket many times during the day while plugging in.

We made the choice of stepper motors because these can be blocked in their movement without burning the motor. As an added bonus the stepper motors are also quiet so that the movement is not audible in a normal working space.

We used 3D-printing to manufacture most of the parts for the moving sockets.

Light patterns

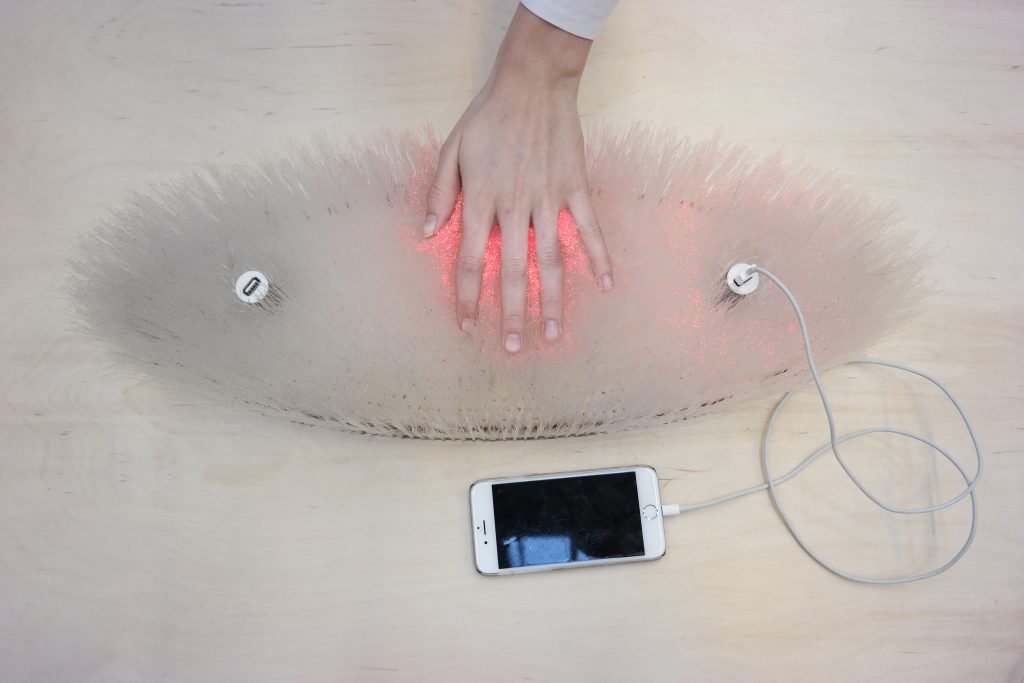

CERUNA’s light patterns respond to the amount of solar energy available. When there is solar energy available CERUNA will display a white light pattern flowing from the edges of the module towards the sockets, motivating users to plug in. The sockets located in CERUNA will rise up to their highest position, making them easily accessible and motivating users to plug in. If CERUNA is touched in this state a white light pattern will follow users’ hands.

At a certain moment, the amount of solar energy can drop again. If users are plugged in at this moment CERUNA will urge them to plug out. A red light pattern will start to flow out from the sockets towards the edges of the module. The sockets begin to drop slowly to make visitors realize the energy source they’re using is changing and motivating them to plug out. If CERUNA is touched in this state a red light pattern will follow users’ hands.

When there is no solar energy available and no one is plugged in, CERUNA will not display any light pattern because it does not want to attract attention. The sockets are in their lowest position, so users have to search between the fibres to use them. When a user does plug in CERUNA will repeat a flowing pattern of red lights every five minutes, reminding him of the grey energy he is using.

Besides the set light patterns, several hidden light effects can be discovered through playing with CERUNA.

Green environment

CERUNA is designed in a modular fashion and can be found throughout the Pulse building area. Our prototypes consist of a wall and a table but CERUNA can be incorporated in many other places, for instance on the floor or on seats.

Research shows that being in a certain recognizable environment reinforces the relevant norms for that environment. By placing CERUNA throughout the Pulse building area a true environment is created, reinforcing the relevant norm of energy awareness.

Some CERUNA modules are also incorporated in the grass in front of the Pulse building where they respond to direct sunlight: a wave of light will flow over the grass when the sun is shining on it. These modules form both a physical and a mental link between the amount of sunlight outside and the CERUNA modules inside.