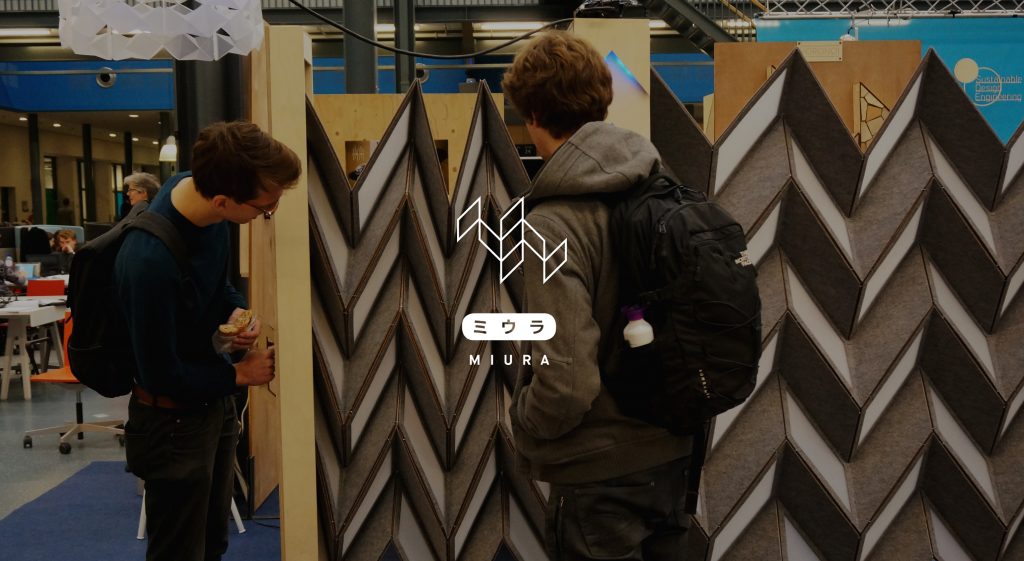

Miura (ミウラ)

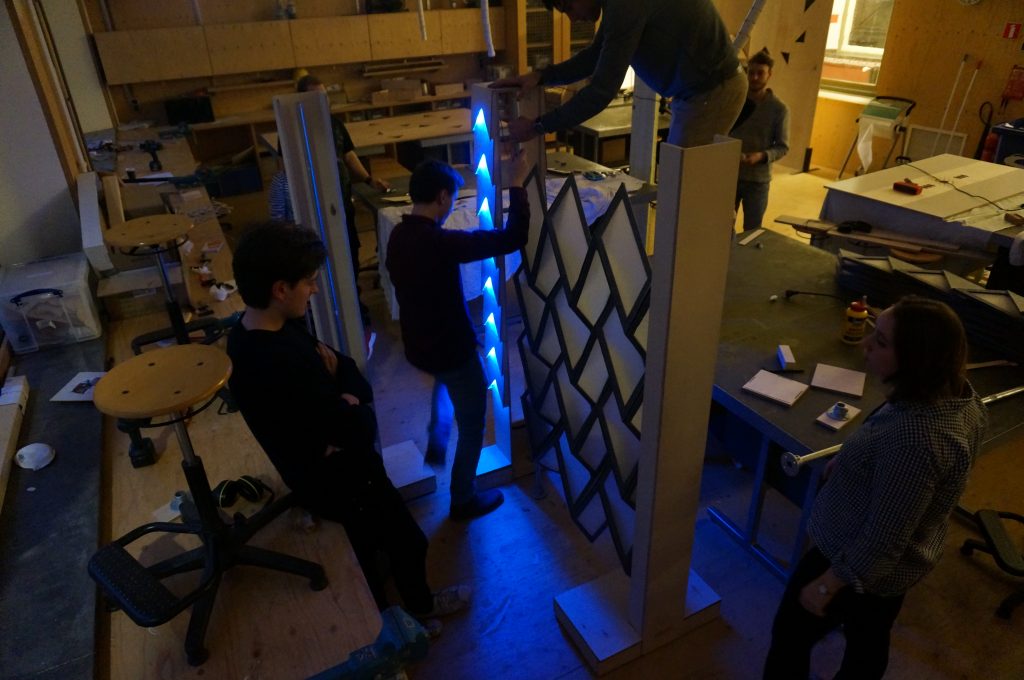

Miura is a flexible partition wall that has been designed specifically for the new Pulse Building at the TU Delft. Using an intricately designed origami pattern it is able to fully extend and retract, creating study areas to suit the student’s needs.

Students: David van der Blonk, Patrick Keesmaat, Max van Manen, Carmen Pepping, Elias van der Linden, Marijke Blom, Alice Coey.

Coaches: Martin Havranek, Aadjan van der Helm, Wouter van der Hoog, Tomasz Jaskiewicz.

In a team of seven, we have been working for the past few months on creating flexible system that both encourages positive working styles as well as complimenting the ideals of the Pulse building.

Using the following pictures we shall explore the progression of Miura from our initial ideas through to the construction and fine-tuning of the concept presented at the final showcase.

Noise dampening.

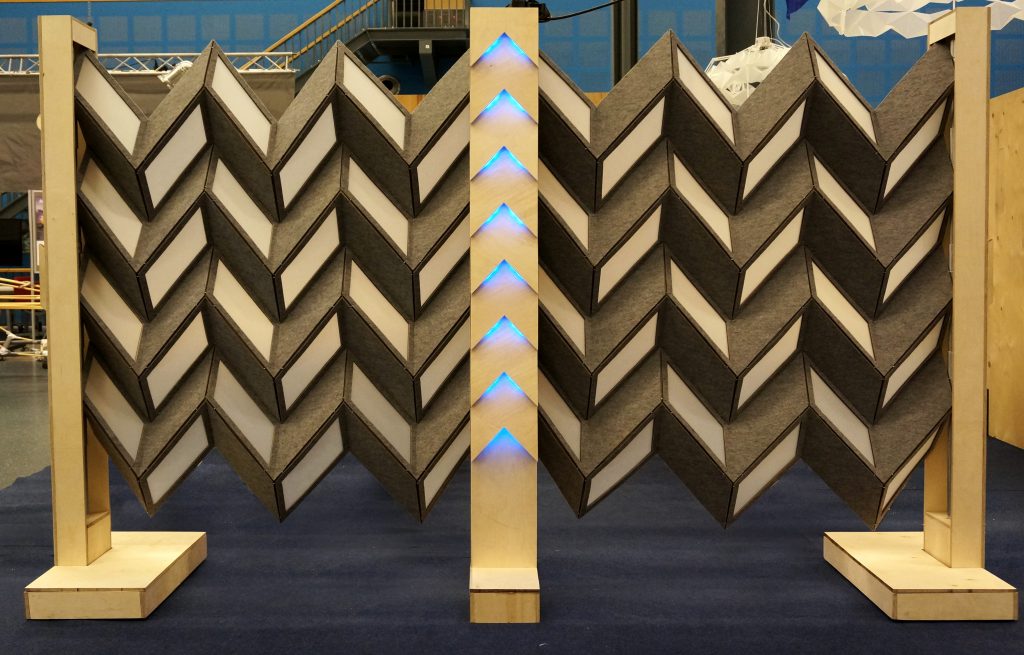

Pulse has a strong emphasis on collaborative and interdisciplinary group work. We envisioned however that conflicting sounds from these various groups would cause distractions and therefore Miura has been specifically designed to minimise this. The research was done into sound absorbing forms and materials and this was fed into the final design solution. The form created when extended is sound absorbing, whilst still allowing light to pass through a pattern of translucent panels. In this way, the wall is able to counteract both audio and visual distractions without compromising the light and airy feeling of the Pulse building.

Early ideation.

Explorations into various ways to cancel noise effectively were carried out, including the use of pockets of air. After extensive exploration of this we concluded that the noise of inflating and deflating this type of wall would cause more distraction than it was solving! From there we started looking at what shapes and materials could be used to dampen sound instead.

Wall behaviour.

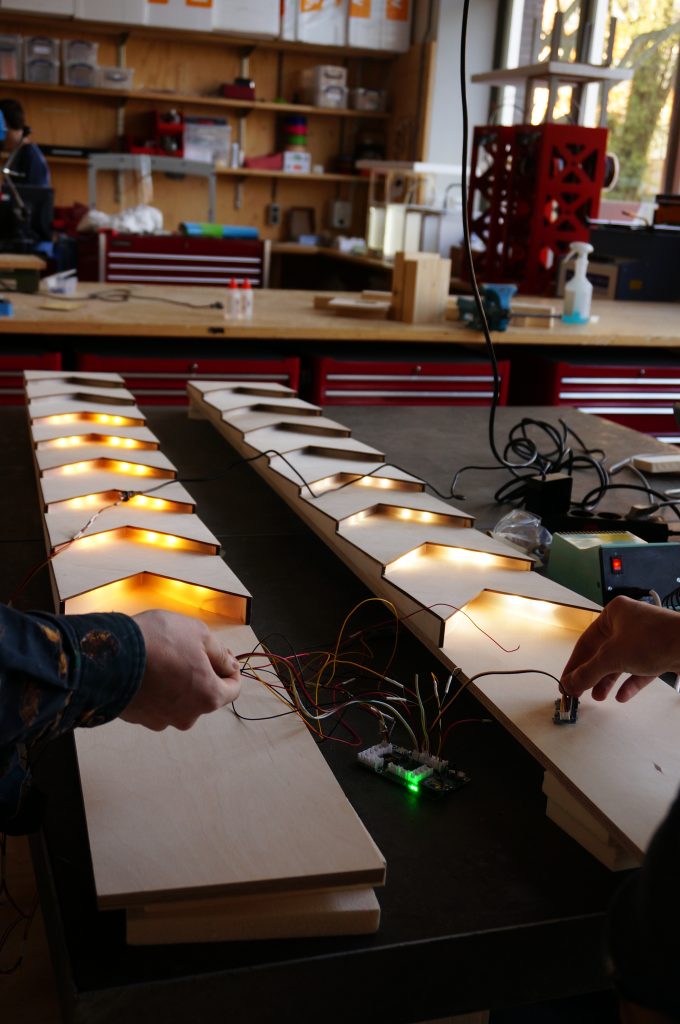

Miura uses sensor data to aid in social amplification. The central pole projects information about noise levels and the occupancy of the surrounding tables and chairs thus aiding people’s choice about where to sit. In this way it helps solve one of the key problems that arose during our user research; that people often find it difficult to see areas that are vacant from afar.

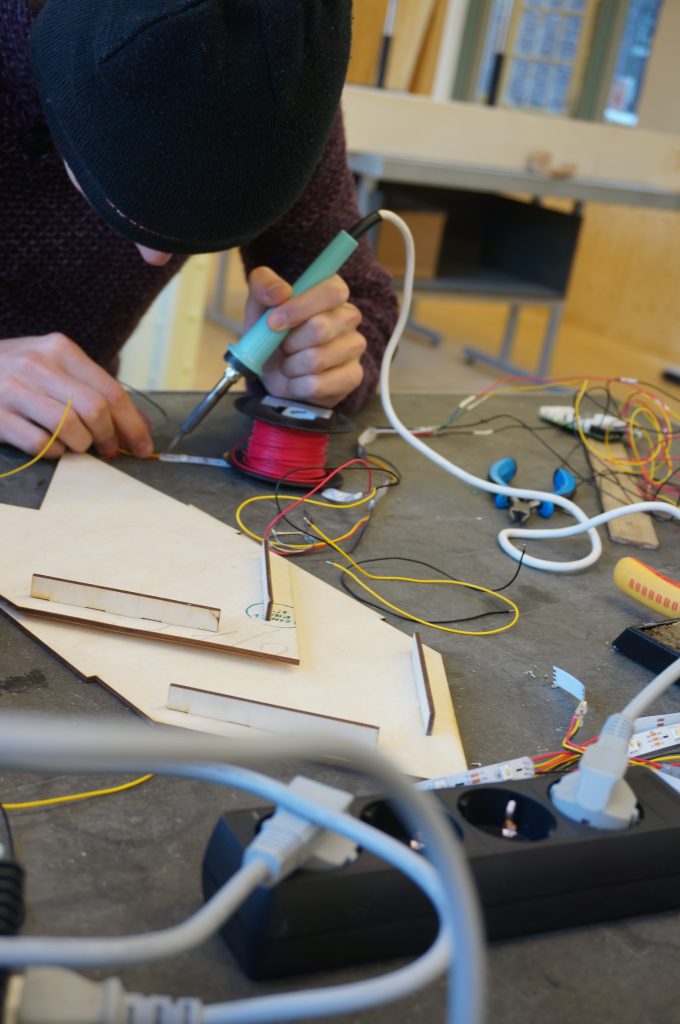

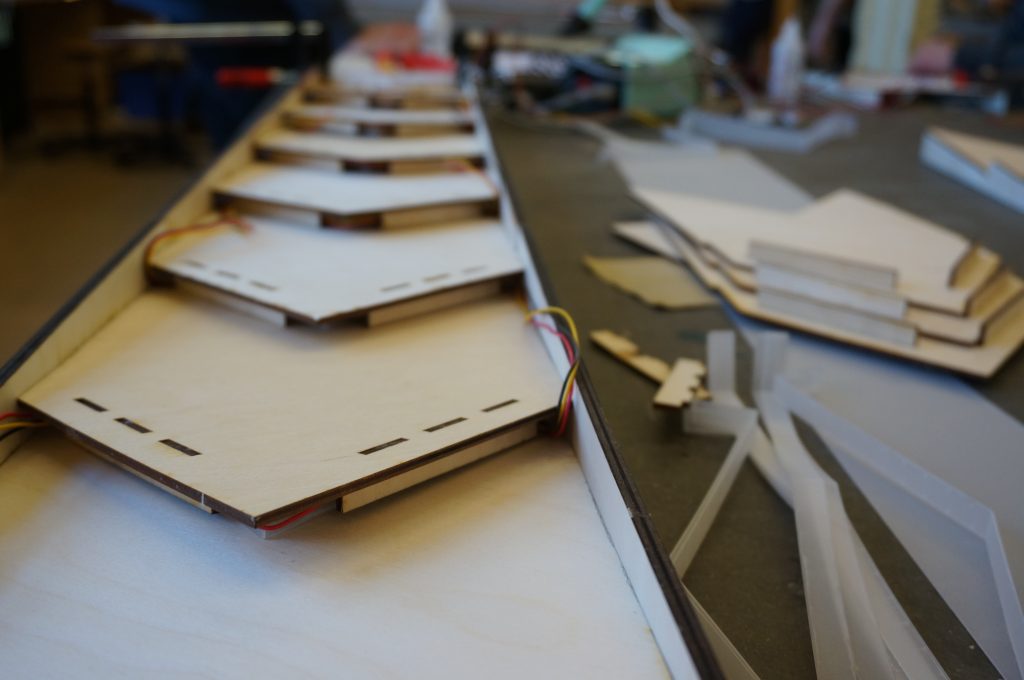

Manufacture.

Tasks were divided between the team for effective workflow. Key areas included electronics, panel manufacture, pole construction, visualisation and storyboarding. Almost all the fabrication was done in-house in an effort to keep costs to a minimum. The felt, however, had to be sent away to have an adhesive film applied and to be digitally cut to the specific shapes we needed.

Materials.

The material choices were driven by several key factors. The panels are made from either solid panels of 3mm plywood or plywood frames surrounding Perspex panels. These were chosen because they were lightweight and easy to cut with the laser cutter and, because the Perspex had the right opacity to provide both light and privacy. The poles are constructed from thicker plywood, proving weight for stability and strength. The natural felt was ideal because of its ability to absorb sound, its strength, and its green credentials.

Problems and solutions.

As with any design process, we encountered a few problems along the way. Lots of experimentation had to be carried out on the felt on how to achieve clean cuts, and how to prevent it pulling away from the wood at the key stress points. We had to outsource the cutting to a private contractor to achieve a quality cut, and the hinges were reinforced at certain points to relieve the stress on the glue.

Miura was exhibited in the TU Delft IO building for a week. In this time students and visitors were invited to use Miura and experience the effect of working in a connected workspace.

https://www.youtube.com/watch?v=nI3vsvXmCrE

Students. Alice Coey, Carmen Pepping, David van der Blonk, Elias van der Linden, Marijke Blom, Max van Manen, Patrick Keesmaat.